This article digs into what changes when food & beverage brands cross the £10m mark, using real founder insights and examples to highlight what goes wrong, and what to do about it.

What’s at stake at £10m+

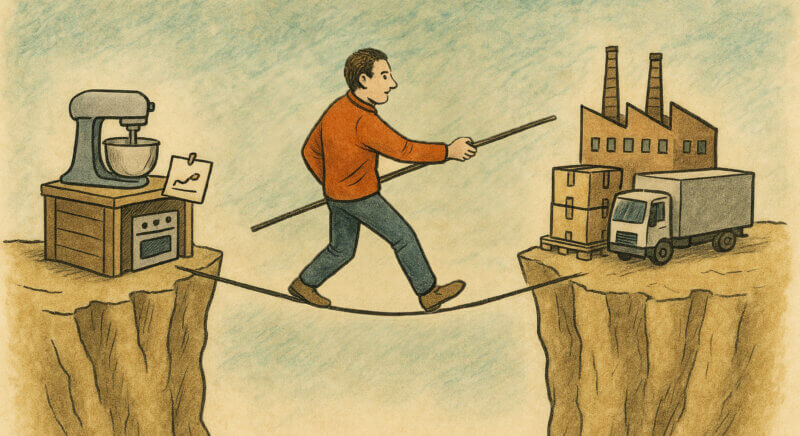

Shift from startup to scale-up mindset

As revenue grows, so do expectations from investors, retailers, teams, and consumers.

Packaging becomes more operational than creative

Design still matters, but issues like minimum order quantities, material cost fluctuations, traceability, compliances, changeovers become more pressing.

Case studies & real voices

Bio&Me

Crossing into mainstream retail required them to not only have design and mission, but also tackle shortages, logistics, regulatory labelling, and material availability. Their work to maintain both credibility and volume under cost pressure illustrates exactly what happens in scale.

Graze

Under Anthony Fletcher, Graze became known not just for clever marketing but for building internal systems that supported packaging and production.

For example: their development of internal tools that allow packaging designs from the design studio to feed directly into manufacturing, cutting manual handoffs.

Common pain points after £10m

Once food brands push past the £10m threshold, a new set of problems tends to surface. Founders often talk about these five in particular:

Supply chain bottlenecks and material shortages

Suddenly you are producing at scale and dependent on global supply chains. Even a small disruption can throw production off track. Bio&Me’s Jon Walsh has spoken about the “great brown cardboard shortage” that threatened their ability to get packaging delivered on time.

Regulatory and labelling complexity

Crossing into multiple categories or markets means packaging has to meet stricter rules. For Bio&Me, that meant ensuring every gut-health claim and ingredient statement was accurate and compliant, while still being engaging for the consumer.

SKU explosion and packaging changeovers

Growth usually means new product ranges. But every extra SKU brings new formats, new designs, and more packaging runs. Bio&Me experienced this when expanding from granolas into porridges, yoghurts, and gluten-free ranges. Graze dealt with it by building internal tools to streamline packaging handoffs between design and manufacturing.

Cost pressures

Bigger volumes should mean better unit economics, but only if you manage procurement and storage carefully. Brands at this stage often risk tying up cash in excess packaging stock or face margin squeeze when material costs rise unexpectedly.

Balancing brand with operations

There’s an ongoing tension between what looks beautiful on-shelf and what actually works in transport and compliance. Bio&Me had to balance colourful, approachable branding with scientific credibility, while Graze invested in systems that allowed their creative vision to be executed without slowing down production.

What to do differently to handle the £10m transition well

- Choose packaging partners who understand both design and function. Not just good art, but supply chain, materials, cost, lead time, compliance.

- Invest in internal tools or processes that reduce friction. E.g. as Graze did, automating handoffs between design → packaging → manufacturing.

- Build in margin for material cost fluctuations. Hedging, buffer stock or flexible supplier terms help.

- Plan SKUs and formats carefully. Extension is good, but proliferation of SKUs can blow up changeover time, storage, and cost.

- Test shelf performance early. Mock-ups, small runs, transport trials can prevent embarrassing or costly failures.

Why packaging sourcing partners should be strategic allies

Delay, error, or misalignment on packaging can cost not just money, but relationships with retailers and consumer trust. For brands at £10m+, a partner who:

- anticipates compliance/regulatory risk

- helps design for shelf, transport, cost

- is agile under supply chain stress

- understands aesthetics + brand storytelling

…those are exactly the qualities founders need. PrintSource can offer that mix, which is what many up-and-coming brands are looking for but find hard to get.

Conclusion

Crossing into the £10m+ revenue range is when startup grit meets industrial expectations. Packaging is no longer just “make it look nice”, it’s mission-critical infrastructure. The more you understand what shifts, what breaks, and what people really care about, the better prepared you’ll be.

If you’re scaling and want a packaging partner who knows how to think ahead

(not just catch up), that’s what Printsource aims to be.